Join us to find

out your own value

Join us to find your own value

Our services

Proposing energy saving solutions

Contributing to the Environment

Proposing energy saving solutions

To operate the plant economically and efficiently, it is necessary to arrange a working environment. It is necessary to analyze the data obtained from detailed surveys and make improvements to ensure that the machinery is operating at maximum efficiency. We provide specific plans, including energy efficiency goals, for customers to decide whether to invest in decarbonisation.

Decarbonization trend in Vietnam

By 2021, Vietnam's solar power growth rate will surpass Southeast Asia, surpassing Japan and France to rank 10th in the world. The Vietnamese government aims to be carbon neutral by 2050, including solar power generation. Decarbonization systems are essential to the industrial world and the adoption of new energy-saving technologies and proper maintenance are the keys to successful decarbonisation.

Green Technology Association/GTA

GTA is an alliance connecting Vietnamese and Japanese companies leading in energy saving technology advocated by SGX JAPAN. In modern industrial society, manufacturing plants are one of the factors that consume a large amount of energy. Today, GTA regularly gathers to strengthen their expertise and contribute to energy conservation by designing systems for equipment throughout the plant, offering advice on optimal maintenance, applying insulating structures and developing an appropriate steam and cooling environment.

Our Materials

required company documents

- LETTER

- Business Guide

- Business Guide

- Business Guide

- TECHNOLOGY

Electrical safety procedures

Business process

ensure safety

Preliminary investigation

Maintenance of machinery and equipment

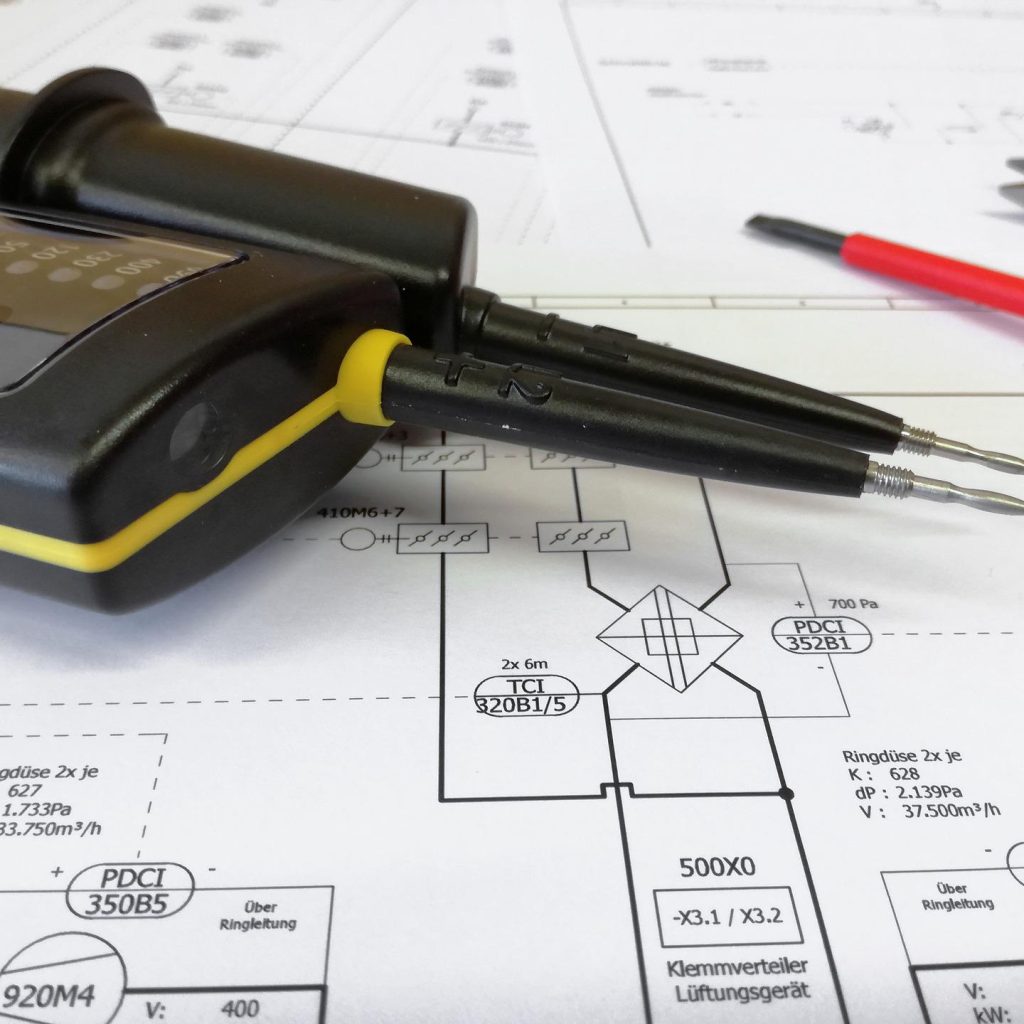

Preliminary research is like examining human health. The health status of the factory can be understood simply by measuring and visually checking the power receiving and distributing equipment of the power system. We will send the results of the investigation, including interviews with the factory, in a report. If it is determined that a detailed inspection is necessary based on the results, the cost of the inspection will be included in the report.

Maintenance inspection and detailed investigation

Maintenance of machinery and equipment

Based on preliminary test results, specific test plans and improvement goals are established for identified problems. Hardware problems require different solutions according to the urgency, so we will discuss with the factory and recommend the best solution. This is a plan that emphasizes the economic efficiency of the return on investment for software problems in order to optimize energy savings and plant operations.

Adjust budgets and make improvements

Maintenance of machinery and equipment

Based on the detailed inspection survey, we estimated the investable plant budget, and resubmitted the detailed plan and budget proposal. We determine the budget based on the selection of necessary equipment, production and construction details, technology and safety management system. Management cost includes survey cost, design cost, construction guarantee cost and maintenance cost for one year.

Periodic inspection and maintenance

Maintenance of machinery and equipment

If there are no issues that need improvement during the preliminary inspection, or if the problem has been resolved with improvement work, we recommend a regular inspection again. Our standards are once a year for high voltage receiving systems, once a month for low voltage distribution systems, and six months to once a year for mechanical equipment. Mechanical devices will be tested according to the manufacturer’s standards and instructions, and oil and specified parts will be replaced.

Accident prevention and emergency response

Maintenance of machinery and equipment

If you have a contract for periodic inspection with the factory, and if there is an unexpected problem or error discovered at the factory, our engineers will quickly arrive on the scene, grasp the situation, determine the correct method. response plan and immediately take the necessary measures. Sort. After resuming operations with urgent measures, we will conduct an investigation to find out the cause and come up with a treatment plan based on the analysis results. Work up to this point is included in the regular inspection service contract.